The Science Behind Biodegradability: How Materials Transform Into Life

In a world increasingly aware of environmental impact, biodegradability has become a key topic in the packaging industry. But what does it actually mean for a material to be biodegradable? How does this process occur, and why does it matter?

Read on to explore the science of biodegradation and how bioplastics are leading the way in sustainable packaging innovation.

What Is Biodegradability?

Biodegradability is the ability of materials to transform into food and nutrients for filamentous fungi and other microorganisms present in the environment. This process breaks down complex materials into simple substances like carbon dioxide, water, and biomass that can reintegrate into the ecosystem without leaving toxic residues.

For a material to be considered biodegradable, it must lose its mass and decompose without generating harmful byproducts. In the case of our packaging, this process takes between 3 and 20 months, depending on environmental conditions.

Factors Affecting Biodegradability

The speed and effectiveness of biodegradation depend on several factors, including material composition, environmental conditions, and the presence of the right microorganisms. Key factors influencing the process include:

- Temperature: Microorganisms involved in biodegradation are more active at warmer temperatures, which speeds up the process. In colder environments, decomposition can slow down significantly.

- Humidity: An adequate moisture level is essential for microorganisms to survive and decompose the material.

The Scientific Process Behind the Biodegradation of Our Products

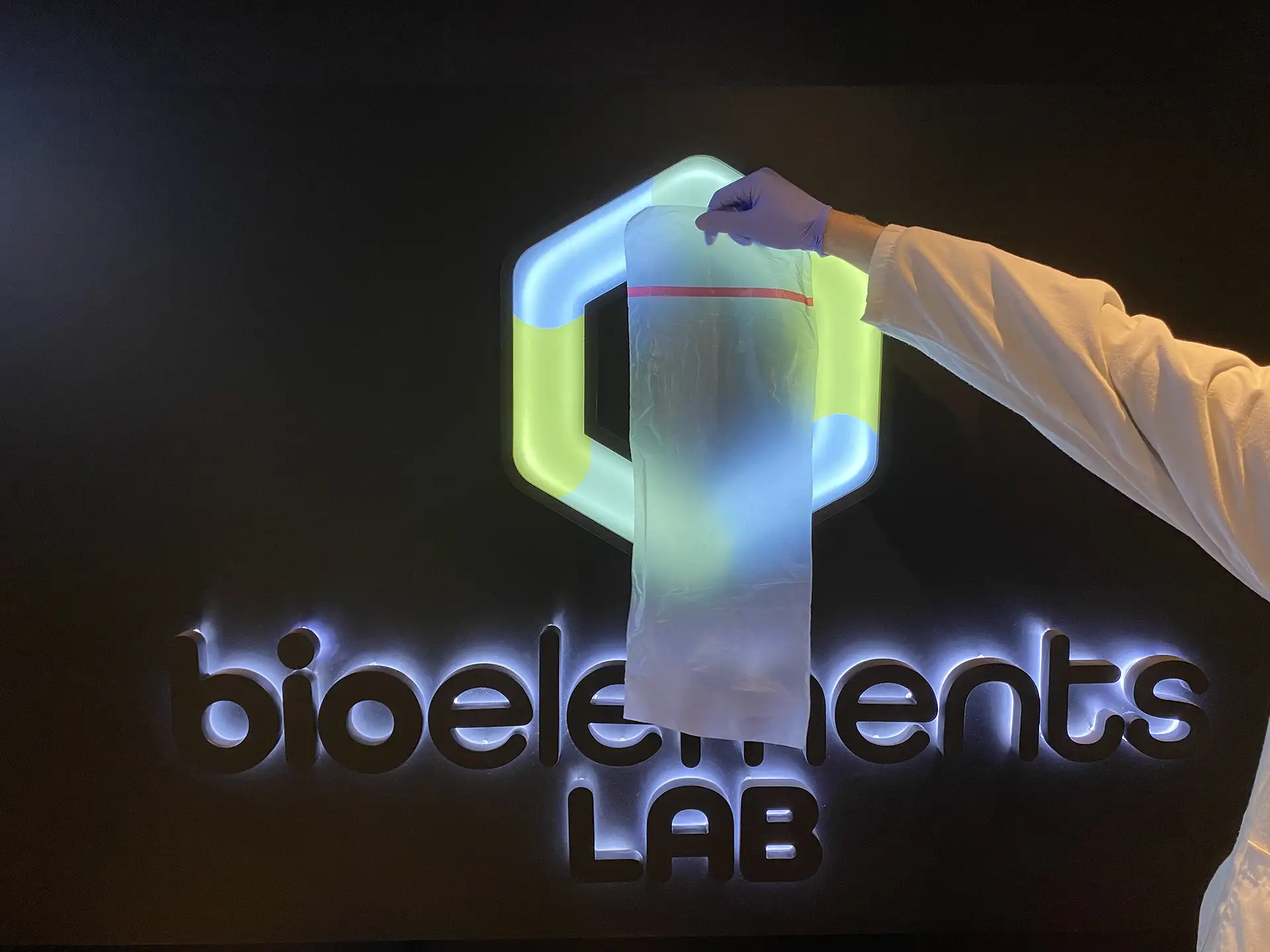

At Bioelements, we have developed over 30 material formulations that biodegrade within 3 to 20 months. This allows us to tailor our biodegradable packaging properties to the specific needs of our clients and the environment where they’ll be used. Thanks to this flexibility, we ensure that our products meet both performance and sustainability requirements.

Our biobags are designed to biodegrade effectively under four types of conditions:

- Landfills: In controlled low-oxygen conditions.

- Composting (home or industrial): Through decomposition processes in controlled environments.

- Natural Environments: Integrating safely into nature without leaving toxic residues.

- Marine Environments: Biodegrading even in marine settings, helping to reduce ocean pollution.

Scientifically validating the biodegradability of each product is a core part of our commitment to sustainability. All Bioelements products are certified or validated by external scientific centers that apply rigorous international standards and methods. We collaborate with leading research institutions like Dictuc in Chile, UNAM in Mexico, PUCP in Peru, UFRJ in Brazil, Universidad de los Andes in Colombia, TUV Austria in Europe, and in the United States, the USDA and BPI.

This comprehensive approach ensures that our products not only meet the highest quality standards but also provide scientifically validated sustainable solutions for a cleaner future.

Why Is Biodegradability Important?

Plastic waste has become one of the biggest environmental issues of our time. It is estimated that only 9% of the world’s plastics are recycled, with the rest ending up in landfills, oceans, and other natural settings, where they can take over 400 years to break down.

By choosing biodegradable packaging like Bioelements’, companies are not only complying with current regulations but also taking a step forward toward a more sustainable future. Biodegradability reduces plastic waste buildup, lowers the carbon footprint, and contributes to ecosystem regeneration.

The Future of Biodegradability

Biodegradability is a scientific solution that can significantly reduce the excess of conventional plastics in the environment. By understanding the science behind biodegradation, both companies and consumers can make more informed decisions that drive real change toward a more sustainable future. This approach minimizes environmental impact and opens the door to a world where new materials work in harmony with the planet.